What is the Thickness of a Panel Door | How Thick Should Your Panel Door Be?

Panel doors are one of the most popular door styles for homes. With their clean, simple aesthetic and variety of design options, it’s easy to see why. But when selecting a new panel door, one important question arises: what thickness should you choose?

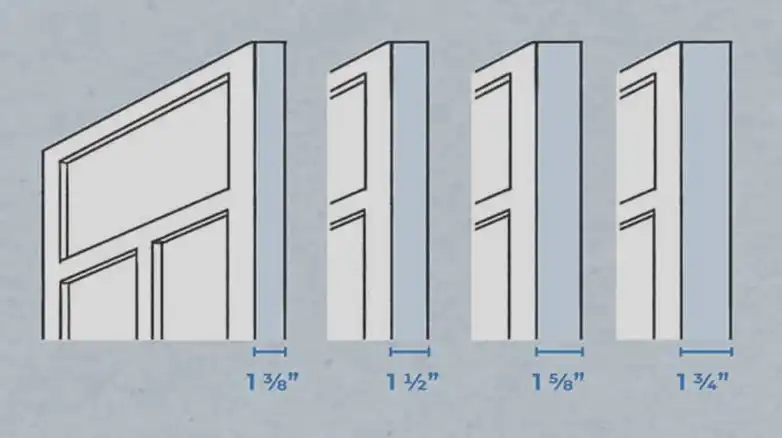

At its core, the thickness of a panel door refers to the overall width from front to back. For a quick answer, interior panel doors are commonly 3/4” to 1-3/4” thick, while exterior panel doors range from 1-3/8” to 1-3/4” thick. But the ideal thickness for your project depends on more than just location. The thickness affects strength, durability, insulation, weight, cost, and even the overall look and feel of a door. By understanding what goes into a panel door’s construction plus your requirements, you can zero in on the perfect thickness.

So, let’s explore the factors that determine panel door thickness, typical ranges, and considerations to help you pick the right option for your needs.

Components of a Panel Door

Before diving into thickness, it helps to understand the basic anatomy of a panel door. These doors consist of two main components:

Source: designingidea

Stiles – The vertical side pieces of the frame.

Rails – The horizontal top and bottom pieces.

The stiles and rails form the outer border of the door. Within this frame sits the panel – the typically flat, central section of the door.

Panel doors get their name from this center panel. It’s most often made of materials like solid wood, plywood, or MDF (medium-density fiberboard). The thickness and type of the panel itself impact the overall door thickness. A solid wood panel tends to add more depth, for example, while a thinner MDF panel keeps the door slimmer.

Now that we’ve broken down the basic components, let’s explore what determines the thickness you need.

Key Factors That Determine Panel Door Thickness

Choosing the right thickness involves weighing several factors.

Application: Exterior vs. Interior Doors

One of the biggest considerations is whether the panel door is for an exterior or interior application.

Exterior panel doors need to be more durable to withstand the elements and changing seasons. Wind, rain, snow, heat, and cold can all wear down doors over time. A thicker exterior door is stronger and more resistant to warping from moisture. That’s why most exterior panel doors range from 1-3/8” to 1-3/4” thick.

Interior panel doors are protected indoors, so they can afford to be thinner and lighter. Typical interior panel door thicknesses are 3/4” to 1-3/8”.

Another minor factor is the amount of traffic through the door. High-traffic entries and passage doors benefit from slightly thicker panels for added durability.

Functionality: Soundproofing, Insulation, and More

The intended functionality is another important driver of door thickness:

Sound insulation – Thicker panel doors naturally offer better soundproofing as they block more noise transfer. Acoustic doors range from 1-3/4” to 2-1/4” thick.

Energy efficiency – Thicker solid wood or insulated doors improve insulation. Exterior doors 1-3/4” or more keep interior spaces more comfortable.

Security – Thicker, solid doors with tight construction resist forced entry. Many metal security doors are 1-3/4” thick or more.

Fire rating – Fire-rated doors adhere to strict thickness standards to contain flames and smoke. Most are 1-3/4” thick.

If soundproofing, insulation, security, or fire rating are concerns, the thickness requirement may be dictated by the door’s rated performance.

Door Style and Design

The style and design details of a panel door also impact its thickness:

Raised panels – Styles like Shaker with deeper, beveled raised panels demand an overall thicker door for rigidity.

Reveals – Thicker doors allow for wider grooves and reveals between panels for shadow lines.

Pre-hung doors – For easy installation, many pre-hung doors follow standard sizes like 1-3/8” or 1-3/4” to work with common hardware.

So in summary, both the functional performance and physical design of a door guide its thickness.

Typical Thickness Ranges for Panel Doors

Now that we’ve covered the factors that go into specifying thickness, let’s look at the typical size ranges:

Interior Panel Doors

- 1/4” – Very thin panel doors for lightweight sliding systems

- 3/8” to 1/2” – Thinner panel doors for simple interior use

- 5/8” – Minimum thickness for many raised panel designs

- 3/4” – The most common thickness for interior panel doors

- 7/8” to 1-1/4” – Mid-range thickness for durability and sound insulation

- 1-3/8” – Popular pre-hung interior door size, heavier duty

- 1-3/4” – Maximum thickness for standard interior panel doors

Exterior Panel Doors

- 1-3/8” – Typical thickness for many exterior panel doors

- 1-3/4” – Most common thickness for durable exterior doors

- 2” to 2-1/4” – Extra thick exterior doors for extreme weather resistance

Regional trends and standards can vary the exact popular thicknesses. For example, many modern interior doors in the UK are 1-3/8” rather than the 3/4” US standard. Be sure to consult your local insulation and fire codes as well.

For a good balance of affordability, practicality, and style, 3/4” offers a great choice for interior doors and 1-3/4” for exterior in most regions. But weigh your specific needs as we’ll explore more below.

Additional Considerations for Choosing Panel Door Thickness

Simply selecting a common interior or exterior thickness isn’t the end of the decision process. Here are a few other factors to consider:

Hardware Compatibility – If choosing a thicker door, ensure the included (or planned) hardware accommodates the size. Thicker doors often require longer screws and specialty hinge sizes.

Weight – Thicker panel doors weigh considerably more than thin ones, which could impact installation. A standard exterior door at 1-3/4” thick can weigh well over 100 pounds requiring heavy-duty hinges and expert installation.

Budget – As you go up in thickness, material and construction costs also rise. Optimal thickness can be a balancing act between needs and budget.

Future Planning – Consider possible future upgrades like adding soundproofing panels into a hollow core door later on. Starting with a thicker door shell leaves room to add upgrades.

Appearance – The thickness subtly impacts the overall look and feel of a door. Thin doors suit modern, minimalist styles. Thick doors make a more substantial visual statement for traditional homes.

Tips for Choosing the Perfect Panel Door Thickness

With all these factors in play, choosing the right thickness for your next panel door project requires careful consideration:

Tip 1: Make a list of your functional needs like insulation, durability, and soundproofing required. This helps narrow suitable thicknesses.

Tip 2: Consider the total look you envision for the space. Do you want a delicate, streamlined door or a bold, heavy door presence?

Tip 3: Review the common thickness standards mentioned above for interior vs. exterior doors as an initial guideline.

Tip 4: Read the specifications of any pre-hung door units or hardware packages that state compatible thicknesses.

Tip 5: Talk to a professional door supplier for specific recommendations based on your application.

Tip 6: Leave a little extra thickness if you anticipate future upgrades like soundproofing.

The time invested to analyze your space, needs, and options pays dividends in getting the perfect final thickness.

Why Door Thickness Matters?

Selecting the proper thickness might seem like a minor detail, but it impacts:

Strength and Durability

Thicker doors stand up to bumps and wear and tear through high-traffic areas without denting or warping over time. Exterior doors resist weather damage more easily at thicker sizes.

Sound Dampening

Thicker doors have greater mass to block noises from transmitting through. Even small increases in thickness noticeably reduce sound transfer.

Insulation

Thicker doors with insulated cores or solid wood construction offer much higher R-Values and better thermal efficiency.

Fire Protection

Fire-rated doors must meet minimum DFPA thickness standards to provide the required fire-resistance rating.

Security

Thicker wood or steel doors deny access longer against forced entry. The thickness makes it harder to break through the door.

Appearance

Subtly, the thickness conveys a sense of modern delicate versus old-world solid. Match personal aesthetics.

The right thickness balances all these factors for your needs.

Conclusion

Panel door thickness is measured from front to back and can range widely from 1/4” for simple interior doors up to 2-1/4” for robust exterior doors. Consider where the door will be installed, the intended functions, door style, weight, cost, hardware, and future upgrades. With an understanding of the factors involved plus local building codes, you can easily select the ideal thickness to match performance, aesthetics, and budget. A professional door supplier also provides specific guidance to pick the perfect size door for every project. While often overlooked, thickness plays an integral role in the overall door quality and usage for years to come.

Relevant Questions

What is the standard thickness for interior doors?

The most common thickness for interior panel doors is 3/4”. This offers an affordable, lightweight option that suits most homes. Interior panel doors typically fall between 3/8” on the thinner side up to 1-3/8” for heavier use.

What thickness should exterior doors be?

Look for exterior panel doors between 1-3/8” and 1-3/4” thick. This provides excellent durability and weather resistance. For extreme climates, 2” or thicker exterior doors add even more protection.

Do thicker doors offer better soundproofing?

Yes, increased thickness improves sound dampening substantially. Even small differences like 3/4” versus 1” make a noticeable difference in blocking noise transfer through doors.

How much thicker are fire-rated doors?

Fire-rated doors must meet UL or NFPA codes for fire resistance ratings. Most are a minimum of 1-3/4” thick with internal layers to withstand flames, but check codes.

Do thicker doors cost more?

Generally, thicker panel doors come with a higher price tag. More materials are involved, and greater precision is required for assembly. Weigh the long-term benefits of thickness versus budget.

How do I know if a door is compatible with my hardware?

Always check hardware specifications for compatible door thicknesses. Adjustable hinges accommodate a wider range. Pre-hung door units match perfectly for easy DIY installations.

How heavy are thicker doors?

Thickness adds significant weight. A 1-3/4” exterior door can exceed 100 pounds. Consider thickness along with size to estimate total door weight and necessary structural support.

What thickness should I choose for soundproofing?

For better sound insulation, go as thick as functionally possible. 1-3/4” or thicker interior doors make a noticeable difference in noise reduction between rooms.